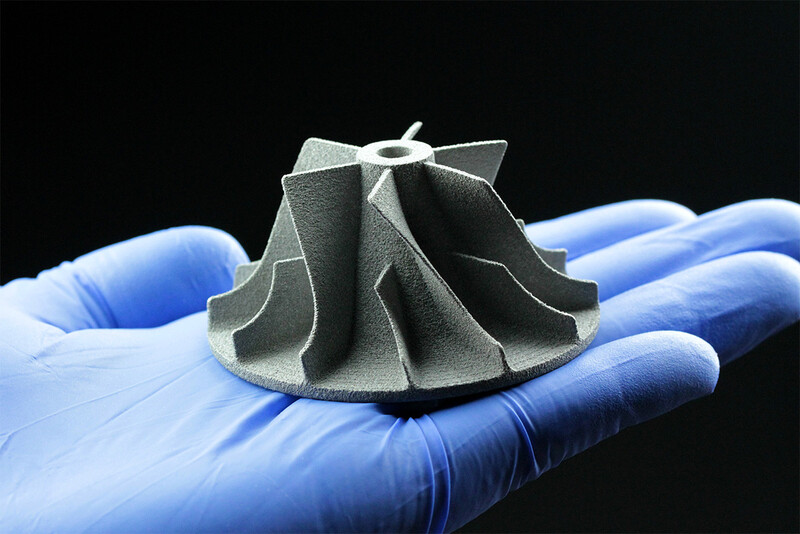

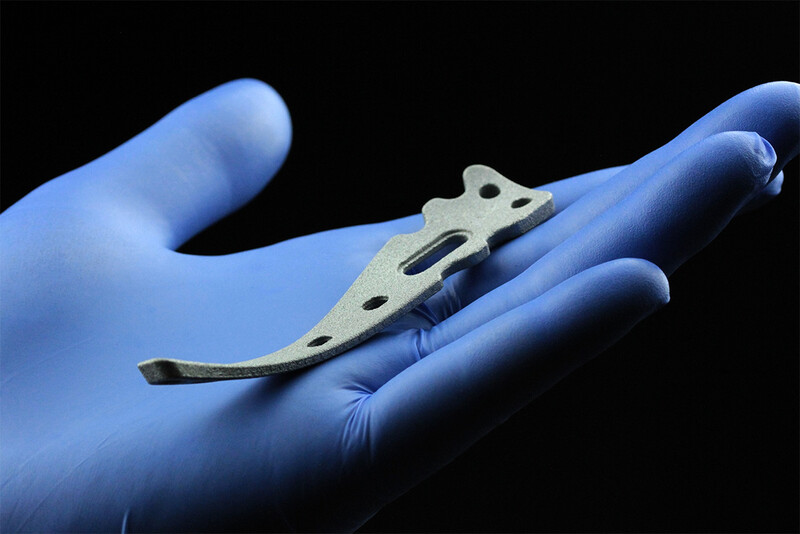

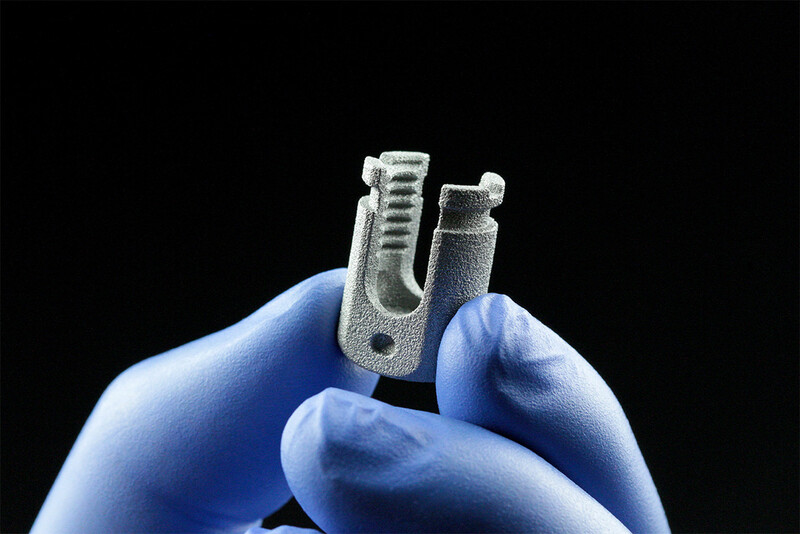

Cold Metal Fusion

Cold Metal Fusion (CMF) is based on integrating metal powder into a functional binder system. It is super fast and already used for many high end applications.

This allows creating a Feedstock system filled with Titanium powder that can be processed on commercially available Selective Laser Sintering (SLS) 3DP systems that are normally used for polymers.

The CMF printing process is quite similar to the Powder Bed Fusion (PBF), but uses much less energy because only the binder that holds the powder together is melted and not the metal powder. This results in increased printing speed and no heat sinks requirements. After the printing is completed, the parts are carefully de-powdered and the remaining Feedstock can be reused.

After printing and de-powdering, the parts require debinding and a sintering process.