Please send us an email

with any questions you might have or a request for quotation and we will get back to you

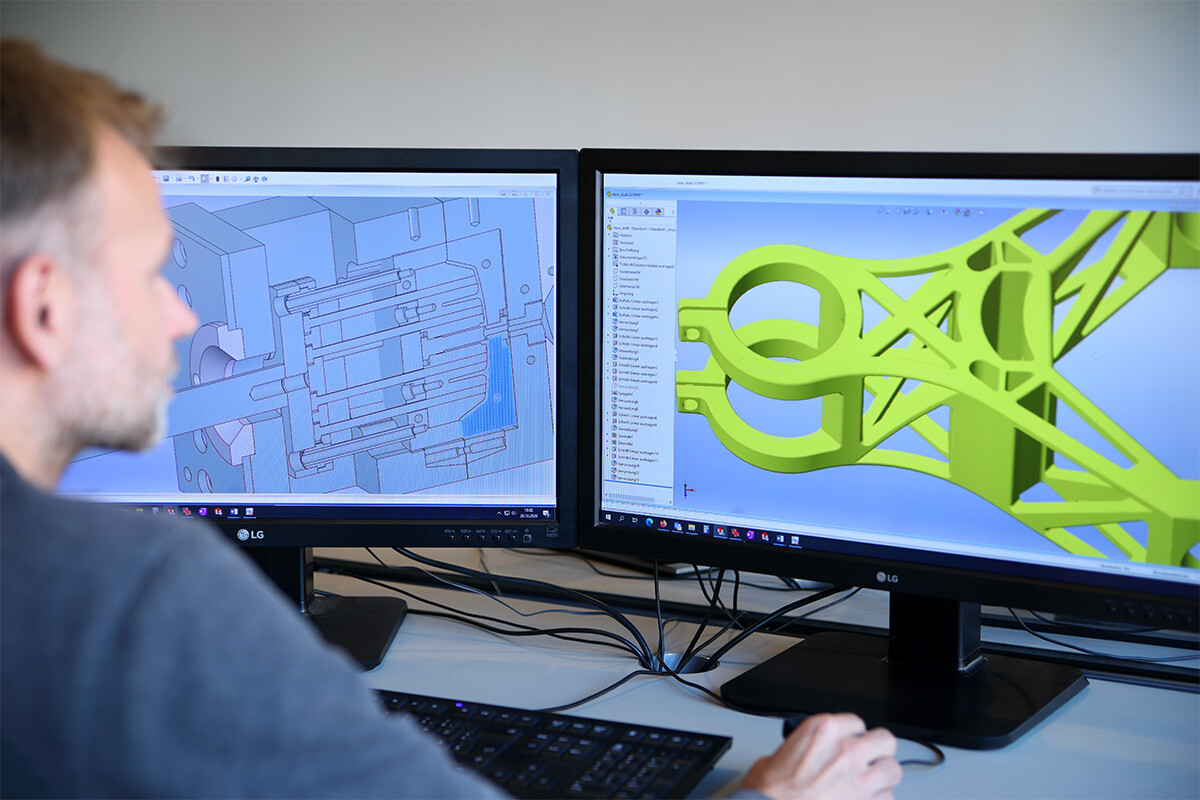

Design for Manufacturing

DFM: Facilitate the manufacturing process, reduce costs and enhance the part properties.

Different forming techniques allow process specific part design and features. As specialists in sinter based shaping technologies, we offer a DFM (Design for Manufacturing) service to find the best shaping process and part geometry.

3D Printing (3DP) allows great design freedom, but parts may have limits in regards to overhangs or surface quality. There are different 3DP technologies and they all have their pros and cons.

Metal Injection Molding (MIM) is still the best choice for high volume, good surface quality and high precision applications, but the design needs to follow certain rules for undercut limitations, wall thickness transitions and draft angles.

Through the use of sinter based shaping technologies, you may include a topological optimized design and you can incorporate density gradients to get the most lightweight and material efficient design. Part complexity is not a cost driver.

Create the design that fits best for your needs. We can help you get there.