Pellet Printing

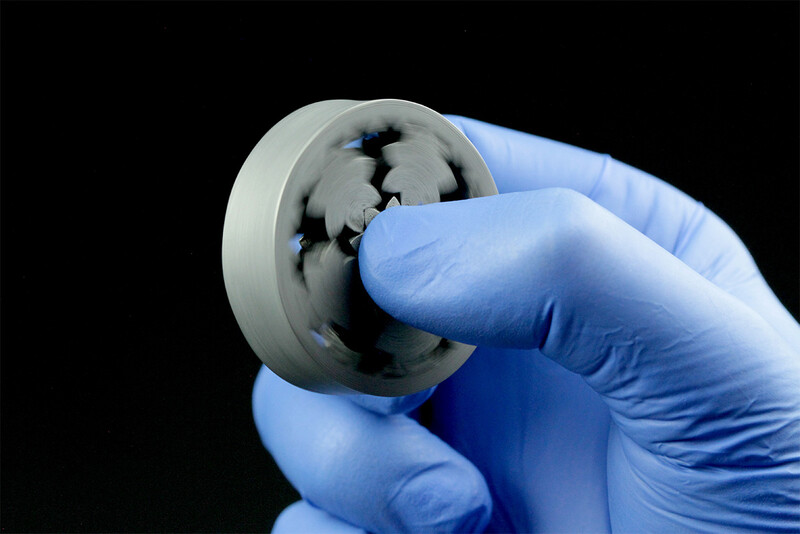

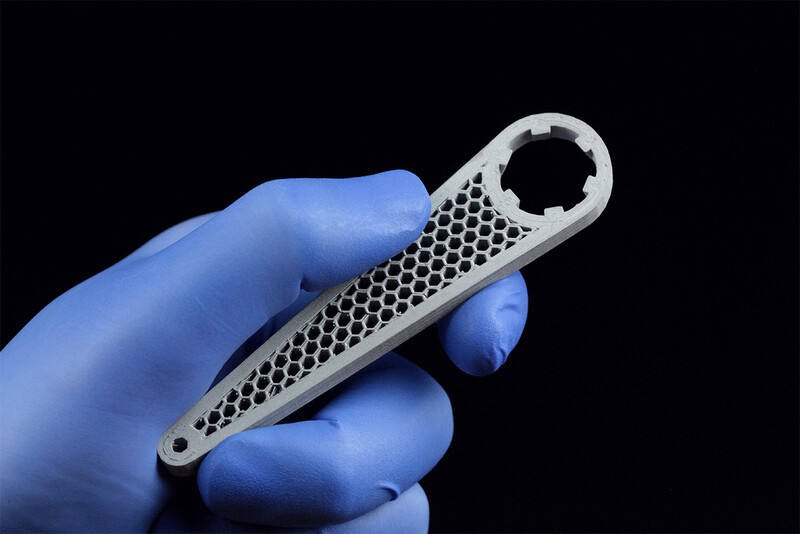

Fused Pellet Fabrication (FPF) is a sinter-based 3D Printing process (3DP) similar to FFF.

The process uses Pellets as raw materialsimilar to Metal Injection Molding. The heated printer head deposits the material layer by layer onto the growing part.

The Titanium Pellets used at Element22 are a mixture of fine Titanium powder and other materials that are needed for processing, the so-called binders. After printing, the parts require a debinding and a sintering process.

We use the FPF technology to create prototypes, but also low volume production for certain applications and quantities. This allows us to use the same feedstock when printing or molding, which simplifies the re-qualification for customers when changing over from one shaping technology to the other.

The Element22 Titanium Pellets are also available for sale so that you can print yourself. Get more information on the Elemen22 raw material here.

Element22 also offers the Debinding and Sintering of printed parts as a service. Get information here.