Get your D&S Token here!

Contact us

Debind and Sinter (D&S) Service

We offer processing of your printed parts in our qualified and validated debinding & sintering equipment.

After successfully printing a Titanium part, the binders in the raw material need to be removed by debinding with a subsequent sintering process step to create the full density and superb material properties.

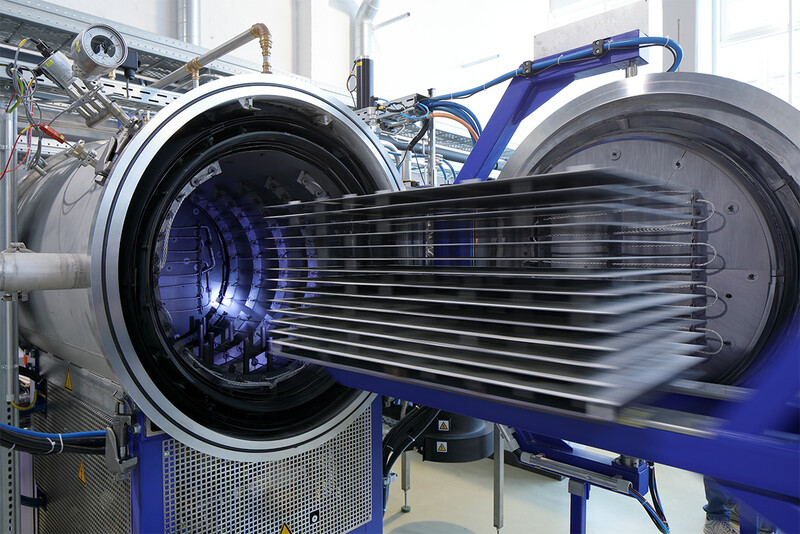

Debinding and Sintering Titanium requires a very high level of expertise and advanced equipment. Any impurities in the Debind & Sinter (D&S) process will lead to poor material properties.

Element22 developed and patented a unique sinter process, which leads to unparalleled material properties.

We offer processing of your parts in our qualified and validated debinding & sintering equipment.

Titanium Generation

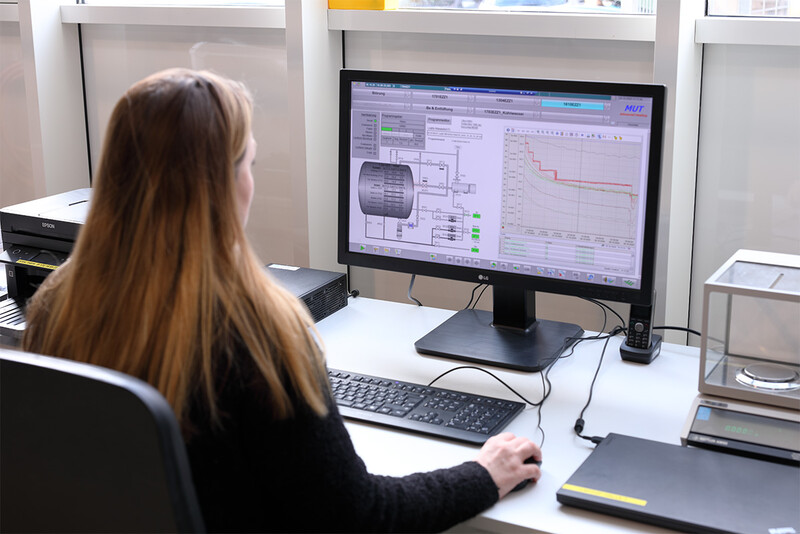

If quantities continue to increase, we can help with picking the best equipment and processes through Titanium Generation GmbH. Titanium Generation is a Joint Venture between MUT Advanced Heating GmbH, Jena and Element22, with focus on heat treatment and thermal debinding & sintering for Titanium Powder Metallurgy (PM) processes like 3D Printing, Metal Injection Molding and others.